Ultimum Rector ut summus temperatus metallum gaskets: types, lectio, et defectum praeventionis

2025.06.19

2025.06.19

Industria News

Industria News

Summus temperatus metallum gaskets Sunt discrimine components in industrias ut oleum & Gas, potestas generationem, eget processus, et aerospace. Et ut Leak-probationem signantes in extrema calor, pressura et mordendo environments. Eligendo ius gasket potest significantly impulsum apparatu perficientur, salutem, et sustentationem costs.

I. optimus High-Temperature Metal Gasket ad Industrial Applications

Key considerations ad Industrial Use

High-temperatus metallum gaskets debet sustinere scelerisque cycling, eget nuditate et mechanica accentus. Maxime commune materiae includit:

Steel immaculatam (CCCIV, CCCXVI, CCCXXI) - bonum modicum calor et corrosio resistentia.

Inconel (DC, DCXXV, DCCXVIII) - optimum est calor optimum (ad M ° C) et oxidatio resistentia.

Titanium & Tzm Alloy - in Aerospace et High-Suspendisse Environments.

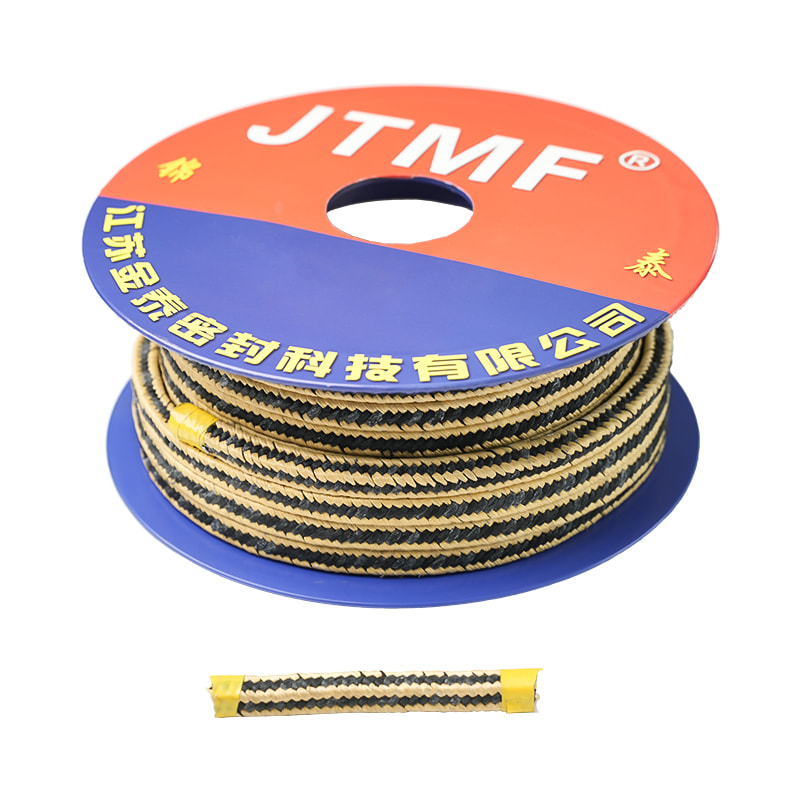

Graphite-repleti spiralem vulnus gaskets - idealis pro summus pressura vapor et eget applications.

Applications in Key Industries

Oleum & Gas - Wellheads, Flanges et Refinery Piping.

Power plantis - Boilers, Turbines et exhauriunt systems.

Donec processus - reactors, calor deicit, et mordere fluidum tractantem.

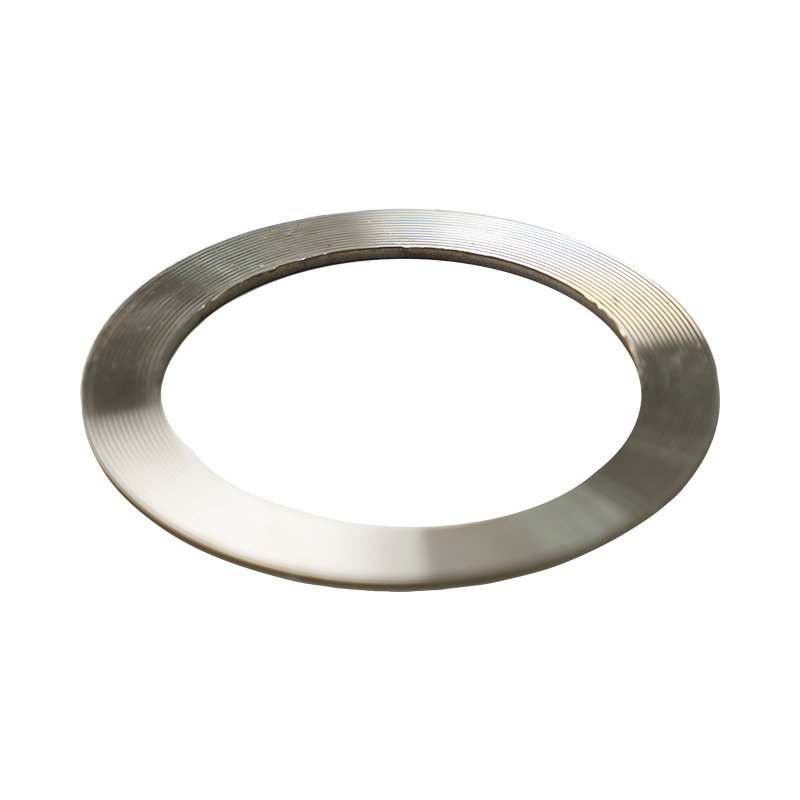

304ss / 316ss CONRUGIS Metal Graphite Gasket

2. Summus temperatus spiralis vulnus gasket : Genera, utitur & Electio Tips

Genera spiralis vulnus gaskets

Latin vulnus VULGATUS (SS304 Graphite) - High-Temperature pro Generalis pro.

Interiorem & exterius Annulum Reinforced - impedit super-compressionem in altus-pressura systems.

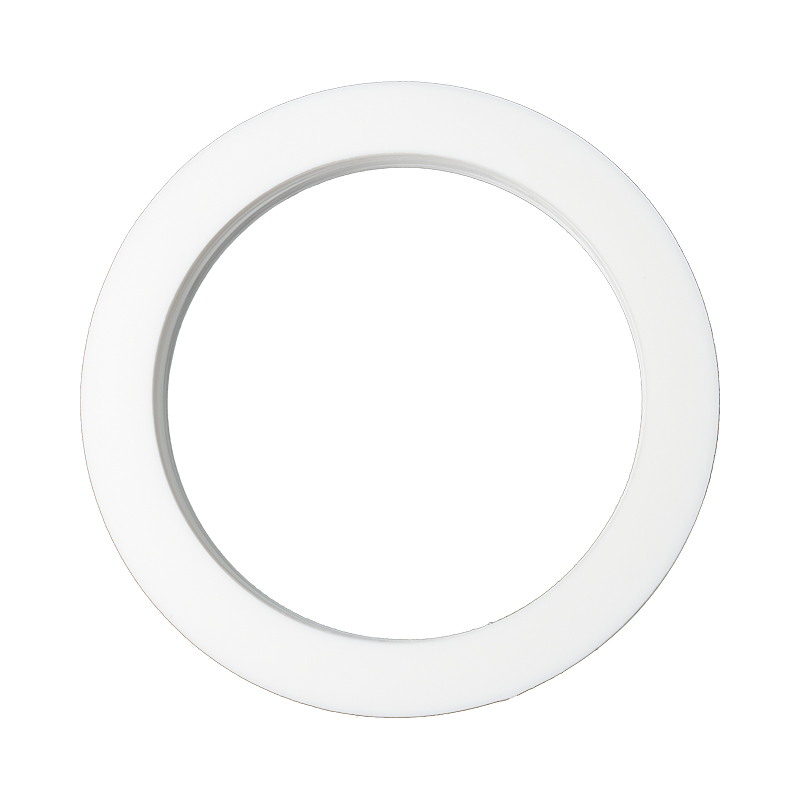

Ptfe-repleti spiralem vulnus - pro chemical resistentia in modice calor.

Ut eligere ius spiralis vulnus gasket

Temperature rhoncus - ensure ad gasket materia can tractamus apicem operating tentat.

Rating pressura - superius PSI requirit confirmat consilia.

Media Compatibility - Reprehendo eget resistentia contra fluidorum / vapores in systematis.

III. Quam eligere ius Metallum gasket ad extremum calor (CCC ° F)

Factores afficiens gasket perficientur in extrema calor

Scelerisque expansion - metallorum expand ad altum tentat; et gasket oportet compensare.

Serpat relaxation - Quidam materiae deformant in longum differentur calor nuditate.

Oxidatio & Corrosion - Quidam Alloys Faster faster in infestantibus environments.

Commendatur gasket materiae ad CCC ° C

| Materia | Tab (° F) | PROPRESSUS | Clavem proprietatibus |

|---|---|---|---|

| Inconel DCXXV | CMLXXX ° C | Summus pressura vapor systems, exhaurit manifolds | Optimum oxidatio resistentia, maintains vires magno tentat |

| Flexibile Graphite | MMM ° C (in inertes Gas) | Flange hospites, calor deicit | Exceptional scelerisque conductivity, chemica inerti |

| Titanium | DC ° C | Aerospace components, eget reactors | Princeps vires-ut-pondus ratio, corrosio repugnant |

| Aliquam Steel CCCXVI | DCCCLXX ° C | General Industrial Applications | Bonum statera de sumptus et perficientur |

| Tzm mixy | MCC ° C | Nuclei applications, fornacem partibus | Temperatus stabilitatem, humilis scelerisque expansion |

IV. High-temperatus Gasket defectum: Causas et ne Rerum

Commune Causis deficiendi

Scelerisque cycling - saepe calefacit / refrigerationem infirmorum in gasket in tempore.

Improprium installation - inaequalibus fulmine loading leads ad effluo.

Chemical impetum - acida, alkalis, aut solvents Deggrade Gasket materiae.

Per-compressionem - adtritis in gasket reducit signare facultatem.

Quam ne Gasket defectum

Uti recta materia temperatus et eget nuditate.

Sequere torque cubits vitare sub / per-tensis.

Inspicere gaskets regularly ad induendum, rimas, aut deformatio.

Considerate Gasket consilio (E.G., Vulnus Vulnus vs. Solidum Metallum) secundum applicationem.