Graphite auto-Signing Technology: Applications et Benefits

2025.07.31

2025.07.31

Industria News

Industria News

Intellegentia Graphite auto-sigillum gaskets et industriae usus

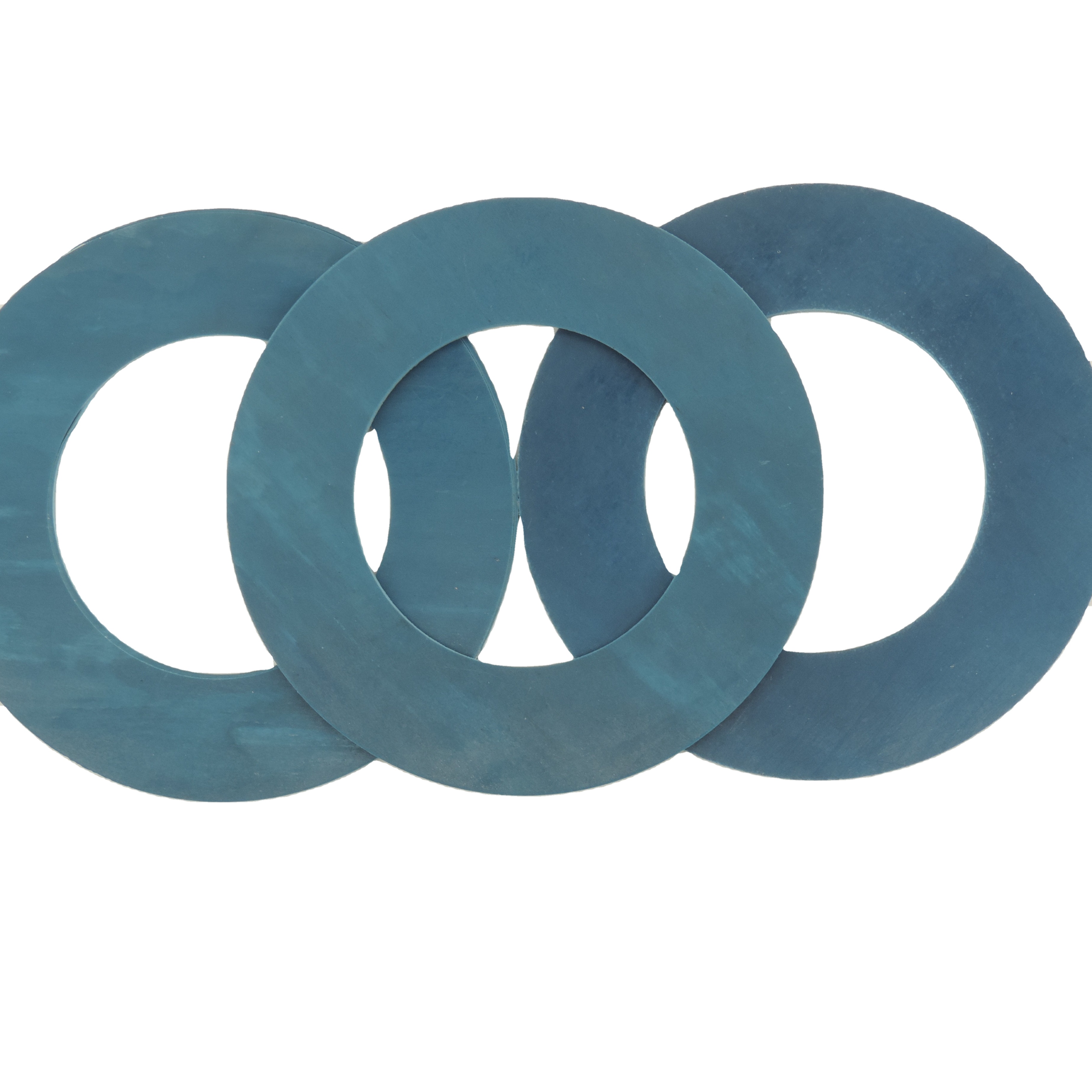

Graphite auto-signatio materiae habent reversed industriae sigillatim solutiones per oblatione superior perficientur in summus temperatus et summus pressura ambit. Dissimilis traditional gasket materiae, Graphite auto-sigillum gaskets Automatice compensare LAGIUM irregularitatibus et ponere stricta signacula etiam in extrema condiciones.

High Temperature flexibile sui signare Graphite Gasket cum corrosio

Quam Graphite auto-Signing Works

Et auto-signing mechanism in graphite gaskets occurs per plures unicum materiam proprietatibus:

- Flexibile Graphite laminis conformis superficiem imperfectionibus

- Thermal expansion creates additional signantes pressura

- Compressionem recuperat maintains sigillum integritas in scelerisque cycling

- Chemical resistentia prohibet degradation ex processus fluidorum

Applicatios in variis industries

Graphite auto-sigillum gaskets Reperio Applications trans Tullius Sectors:

| Industria | Application | Beneficia |

|---|---|---|

| Oleum & Gas | Pipeline Flanges, calor deicit | Resistat princeps pressura et mordax fluidorum |

| Generatio | Vapor Turbine Systems | Optimum scelerisque stabilitatem ad extrema temperaturis |

| Eget processus | Reactor vasa | Repugnant eget impetum |

Commoda High Temperature Graphite signacula Super conventional materiae

Quando comparet High Temperature Graphite signacula Ad traditional signa materiae, pluribus clavis differentias facti apparent:

Temperatus perficientur collatio

| Materia | Maxime continua temperatus | Scelerisque cycling euismod |

|---|---|---|

| Graphite | CDL ° C (DCCCXLII ° F) in Oxidizing, MMM ° C ((V) CDXXXII ° F) in iners | Optimum - maintains sigillum per iteratur cycles |

| Flexilis | CXX ° C (CCXLVIII ° F) Typical | Pauper - Degrades cum scelerisque cycling |

| Ptfe | CCLX ° C (D ° F) | Fair - frigus fluxus exitibus ad altum temperaturis |

Long-term reliability factores

Et diuturnitatem High Temperature Graphite signacula Caules ex aliquot materia characteres:

- Oxidatio resistentia ad elevatum temperaturis

- Minimal serpit relaxationem comparari Polymer, secundum signacula

- Sustentationem mechanica proprietatibus contra wide temperatus ranges

- Superior resistentia ad scelerisque inpulsa

Flexibile Graphite sarcina Material Nam rotating apparatu applications

In pump et valvae caule stipare applications, Flexibile Graphite Packing Material offert distincta commoda super traditum braided stipare.

Installation et perficientur characteres

Propriis installation of Graphite sarcina postulat operam ad plures factores:

- Pre-compressionem annulos ante institutionem

- Sterngered iuncturam noctis in multiple anulum installations

- Herpesviridae

- Confractus-in operandi ratio ad constituere propriis sectionem superficies

Comparative perficientur metrics

| Parameter | Graphite Packing | Conventional stipare |

|---|---|---|

| Scelerisque conductivity | High - Dissipates frictional calor | Minimum - Heat Build In Exitus |

| Compressor | Optimum - conformis ad hastile | Variabilis - pendeat in materia |

| Chemical resistentia | Exceptional - inerti ad maxime chemicals | Formula dependens |

Ecfectio Graphite sheet scelerisque administratione Solutions

Graphite sheet scelerisque administratione Has facti magis momenti in electronics, aerospace et industria applications debitum ad unicum compositum proprietatibus.

Key proprietatibus ad scelerisque applications

- Anisotropic scelerisque conductivity (altus in-planum, humilis per-planum)

- Ad metallum calor spreaders leve comparari

- Conformability ad inaequaliter superficiebus

- Electrica proprietatibus proprietatibus

Consilio considerations

Cum exsequendam Graphite scelerisque solutions, engineers est considerandum:

- Orientation de sheet ad calor fluxus

- Interface materiae et scelerisque contactus resistentia

- Mechanica tutela fragile laminas

- Enormitasal factores afficiens diu term perficientur

Scientia post Self-Lubricating Graphite Components

Self-Lubricating Graphite Components Provide sustentationem-liberum operationem in applications ubi conventional lubricants deficient.

Mechanisms auto-lubricatae

Graphite est Lubricating Properties originate ex eius crystallina structuram:

- Lamellar structuram permittit facile tondebis inter basalia plana

- Adsorbed umor films augendae lubricity

- Transfragum films develop in counterfaces

- Rutris particulas agere ut volvitur elementa

Perficientur in extrema environments

| Environment | Graphite euismod | Alternative materiae |

|---|---|---|

| VACUUM | Optimum - non Outgassing | Most lubricants deficere |

| Radialis | Bonum - maintains structuram | Polymers Dragre |

| Cryogenic | Fair - reducitur lubricity | Liquida solidatur |

Future Developments in graphite signing technology

In agro Graphite-fundatur signantes usque ad evolve cum nova materia formulae et applications.

Emergentes trends et innovations

- Hybrid materiae combining graphite cum aliis provectus materiae

- Nanostraurtructured Graphite ad Auctus Properties

- Eminentive vestibulum complexu Graphite components

- Improved oxidatio resistentia coatings

Challenges et occasiones

Dum graphite signantes solutiones offerre numerosis beneficia, quidam challenges manent:

- Sumptus considerations ad altus-perficientur grades

- Tractantem et institutionem iudicium

- Material limitations in certa eget environments

- Opus ad normatum testis methodologies