Glandulae Glandulae Packing: De ultimo Rector ut Electio, Installation, et Optimization

2025.07.03

2025.07.03

Industria News

Industria News

Comprehensive intellectus graphite glandem sarcina technology

Glandula glandem sarcina repraesentat a significant incrementum in signare technology, offering unica perficientur in exposcens industriae applications. Secus conventional stipare materiae, Glandsing-Glandsing Graphite Combines eximia scelerisque proprietatibus insigni eget stabilitatem. Et material est unique crystallina structuram praebet et lubricity et mollitiam, faciens praecipue valuable in applications ubi traditum sarcina non deficient premature.

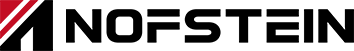

Ignis sentinam valvae stipare glands ipsum fiber graphite glandem sarcina

1.1 scientia post graphite superior perficientur

Exceptionalibus proprietatibus graphite stipare caule ab eius molecular structuram et vestibulum processus:

- Crystallina alignment : Et structuram sino facile hexagonal structuram concedit in securus tondebo inter layers, providing naturalis lubricatae

- Scelerisque conductivity : Cum values vndique a 25-470 w / Mc fretus in gradu, longe excedit organicum materiae

- Oxidatio resistentia : Special treatments potest extendere superiori temperatus terminum per 100-150 ° C oxidizing environments

Recent studiis comparet graphite ad alternative materiae demonstrare patet commoda:

| Res | Expanded graphite | Ptfe compositum | Aramid fibra |

|---|---|---|---|

| Max continua Tempus | 450-600 ° C | CCLX ° C | CCC ° C |

| Scelerisque conductivity | 25-150 W / MK | 0,25 w / MK | 0.04 w / MK |

| PRAETEX | 10-15% | 25-40% | 15-25% |

| ph dolor | 0-14 | 0-14 | 4-11 |

1,2 Industrial Applications, ubi Graphite Express

Quod unique compositum de proprietatibus facit Graphite sarcina idealis pro numerosis provocatione applications:

- High-temperatus Pumps : Maxime in Refinery et Petrochemical Services, ubi temperaturis excedunt CCC ° C

- Eget processus : Handling infestantibus media inter fortis acida et alkalis

- Vapor Systems : Et saturatum et superheated vapor applications usque ad C bar

- Gyratorius Equipment: agitators, mixers et alia apparatu cum eccentrici motus

Optimus Practices pro Graphite CYMBALON Stem stipare installation : A gradum-per-gradus Magister Guide

Propriis installation methodologia est crucial ad consequi optimal perficientur a Graphite CYMBALON Stem sarcina . Processus requirit praecisione et operam detail in omni gradu, ex praeparatione ad finalem disparet.

2.1 comprehensive pre-installation praeparatio

Praeparata Rationes ad XL% of stipare perficientur secundum industria studiis:

- Apparatu inspectionem : Mensura sagitta / Diameter ad multa puncta ad reprehendo ad gere (typice non excedunt 0,1mm dissident)

- Superficies metam verificationem : Specimen superficiem asperitas (RA) sit 0.4-0.8μm ad optimal perficientur

- Purgato arca sagina : Remove omnes vetus sarcina residua per specialized catulos et perterget, sequitur solvendo Purgato

- Stipare mensurae : Quin Packing Cross-sectioni dimensiones ad intus ± 0.1mm de spissamento arca archa alvi

2,2 Advanced Installation Techniques ad maximum perficientur

Institutionem processus requirit methodical executionem:

- Pre-formatam annulos : Circumcirco stipare circa recte amplitudo Mandrel pre-forma ante institutionem

- CONLECTORIUM : Turbabantur articulis exacte XC ° pro etiam, numerati sunt, aut CXX ° tres-layer sets

- Compressionem sequence : Applicare initial compressionem ad L% of ultima valore, tunc operantur apparatu ante ultima tensis

- Confractus, in procedure : Paulatim auget pressura / temperatus super 24-48 horas ad optimal seating

High Temperature Graphite Packing enim Vapor Applications : Engineering Consid

Vapor systems praesenti unique provocationes quod demanda specialized High Temperature Graphite Packing enim Vapor Applications . Intelligentes haec necessaria est ad certa diu term perficientur.

3,1 scelerisque dynamics et eorum impulsum in perficientur

Graphite sarcina gerit aliter sub vapor condiciones comparari ambientium temperatus:

- Thermal expansion coefficientes : Axial expansion of 0.5-1.2mm / M ad CD ° C postulat propriis glandulae temperatio

- Calefacere translatione characteres : Graphite est summus conductivity (usque ad CL w / mk) adjuvat dissipare frictional calor

- Vapor extinguat effectus : Celeri Refrigerant Cycles potest causare Micro-fracturing in inferior species Graphite

3.2 pressura, velocitas (PV) considerations in vapor ministerium

In relatione inter pressura et velocitas critico afficit stipare vitae:

| SERVITIUM | PV Limit (Mpa · M / S): | Expectata vitae |

|---|---|---|

Humilis pressura vapor (| 2.5-3.0 | 3-5 annorum | |

| Medium pressura Vapor (10-40 Bar) | 1.8-2.5 | 2-3 annorum |

| Princeps pressura vapor (> XL bar) | 1.2-1.8 | 1-2 annis |

Graphite Packing Leakage praeventionis Techniques Nam missione, discrimine systems

DEFECTARIUS Graphite Packing Leakage praeventionis Techniques Exigit intellectus tam fundamental principia provectus methodologies.

4,1 et Leakage Control Pyramid

Efficens Leakage praeventionis operates in multiple campester:

- Primaria signacula : Propriis sarcina lectio et installation

- Secundarium controls : Cordern Annulis et iniectio Systems

- Tertiariis mensuras : Collection systems et environmental imperium

4.2 Advanced Leakage Management Systems

Moderni plantis uti sophisticated techniques ad minimize Leakage:

- Laser alignment Systems : Entry <0.05mm runout ad discrimine soliferis

- Smart Glandulae sectatores : Spring onusto designs ponere constant compressionem

- Condition Cras : Vibrationis Analysis et scelerisque imaging praedicere defectis

Comparet flexibile Graphite nobis Argum Graphite Packing : A detailed technica analysis

Ad arbitrium inter Flexibile Graphite nobis Argum Graphite Packing Technical factores involves diligenter.

5,1 structural et perficientur characteres

Differentiae fundamentalis inter duo genera:

| Proprium | Flexibile Graphite | Arthur Graphite |

|---|---|---|

| Densitas range | 1.1-1.3 G / CM³ | 1.0-1.2 G / CM³ |

| Tensile viribus | 4-8 MPA | 10-15 MPA |

| Compressor | 30-40% | 25-35% |

| Recuperatio rate | 15-25% | 10-20% |

5,2 applicationem-specifica lectio matrice

Decision factores ad variis operating conditionibus:

- Summus temperatus static signacula : Flexibile Graphite malle ad superiorem serpere resistentiam

- Dynamic applications cum vibrationis : Braided Construction Potius Handles mechanica accentus

- EXPOSITUM : Flexibile Graphite praebet Purer Graphite contentus

Advanced sustentacionem Strategies pro Glandy Glandem Systems

Proactive sustentationem extenditur ministerium vitae et reduces totalis sumptus dominium pro graphite sarcina installations.

6,1 Predictive Sustentacionem Techniques

Moderni Adaicit ad stipare sustentationem:

- Thermographic vigilantia : Track temperatus profiles ad deprehendere abnormes friction

- Acoustic emission temptationis : Identifies microscopic leaks antequam facti visibilis

- Perficientur trending : Log Leakage Rates nos Operating Horae ad praedicere finem-of-vitae

6,2 Troubleshooting Flowcharts pro Commune Exitus

Systematica aditus ad quaestionem resolutio:

- Nimia leakage : Reprehendo compressionem → inspicere Skaft → Quin alignment

- Celerium : Review PV valores → Reprehendo lubrication → examine Superficiem metam

- Summus attritu : Quin confractus-in procedure → Reprehendo pro super-compressionem